E-Archive

Science Update

in Vol. 3 - November Issue - Year 2002

Assessment of a shot peened surface with the micro-magnetic method

Dr. Janez Grum

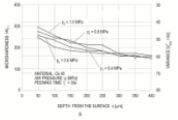

Figure 1A: Microhardness profiles below the surface layer, with different shot peening time: t1 = 30 s

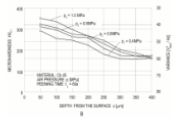

Figure 1B: Microhardness profiles below the surface layer, with different shot peening time: t2 = 60 s

Figure 2: Average residual stresses through shot-peened layer at different air pressures and with different shot-peening times

INTRODUCTION

Shot peening is a process of mechanical hardening of the surface layers of machine parts applied in order to ensure compressive residual stresses in these layers. The compressive residual stresses in the surface layer improve: fatigue strength of a material, resistance to fretting fatigue, and stress-corrosion resistance.

In the assessment of the quality of the shot-peened layer, the highest value of the compressive stress at the surface or just below it and the gradient of compressive stress are of major importance. Suitably selected machining conditions may ensure ideal variations of residual stresses in the shot-peened layer of a machine part so that the required life may be achieved. In practice the quality of surface layers is mostly determined by various destructive testing methods applied to specimens specially prepared for a microstructural analysis, hardness measurements, and measurements of residual stresses. In case of larger series of machine parts, measurements of a sufficiently large number of machine parts are needed to be accomplished, and the adequacy of machining to be confirmed by statistical processing of the results obtained [1,3,4,5,8,9].

To this end non-destructive methods have recently become established, particularly due to their direct applicability to material analyses of machine parts and their suitability for integration into automated production systems. For successful implementation of the complex non-destructive testing methods, the development of sensor technique for capturing signals and computer techniques for processing and analysing test results are of key importance. One such non-destructive method is the micro-magnetic method based on the Barkhausen noise. This method permits non-destructive determination of the type of microstructure, hardness, i.e., microhardness, of a material and determination of the extent and variation of the residual stresses in the thin surface layer of a material [2,6,7].

EXPERIMENTAL PROCEDURE AND RESULTS

Material and specimen preparation

For the study of shot peening, flat specimens made of a Ck45 heat-treatment carbon steel with 150×45×8.0 mm in size were chosen. Prior to shot peening, the specimens were annealed at a temperature of 680 °C in order to reduce the residual stresses present because of previous machining. The annealing temperature being the same for all the specimens, it could be presumed that prior to shot peening they were all the same. This permitted an efficient comparison of different cold-hardening conditions. The experiment was performed with a shot-peening device consisting of a compressor, Atlos Copeo XAS 350, with a Venturi nozzle made of silicon nitride and with a diameter of 8 mm.

The optimum distance between the nozzle and the specimens, i.e., 150 mm, in shot peening was determined in previous tests aiming to ensure a uniform cold hardening across the entire specimen width. The peening shot chosen was a material with a trade mark of S 170SP and an average grain diameter of 0.5 mm. The flow rate of the grains depended on the air pressure chosen. With a pressure of 0.9 MPa it was equal to approximately 8.0 kg/min. Shot peening was performed with four different pressures, i.e., 0.4, 0.6, 0.8, and 1.0 MPa, and with two peening times, i.e., 30 s and 60 s.

Microhardness

Hardness of the base material, i.e., Ck 45, in the soft state ranged between 160 and 175 HV. Fig, 1 shows the through-depth variations of microhardness with reference to the peening conditions including different air pressures and different peening times, i.e., t1 = 30 s (Fig. 1A) and t2 = 60 s (Fig. 1B).

The data in the diagram indicate:

· that the surface microhardness and its through-depth variation depended on the air pressure; it ranged between 250 and 300 HV0.1 with the shorter peening times and between 290 and 355 HV0.1 with longer peening times, depending on the air pressure;

· that with an increase in the air pressure, the through-depth microhardness of the shot-peened surface layer increased as well, the microhardness gradient between the highest and the lowest air pressures chosen amounting to HV0.1 = 65 and then decreasing with depth to HV0.1 = 20;

· that the variation of microhardness to a depth of 400µm was gradual, which had a very favourable influence on an increase of fatigue strength of the material, i.e., a machine part;

· that the depth of shot-peened layer was almost independent of the air pressure and the peening time.

Residual stress analysis

Fig. 2 shows increased values of the residual stresses at the different air pressures and after the different peening times. The measured residual stresses represent an average value up to a depth of 400 mm of the shot-peened layer. The residual stresses concerned were compressive and ranged, depending on the air pressure, between –310 and –390 MPa with the shorter peening time t1 and between -410 and -490 MPa with the longer peening time t2.

CONCLUSIONS

For determination of the stress condition in the material, the comparative way of measurement, including determination of the stress calibration curve in the first phase, was used. Processing of the captured voltage signals was accomplished with the method of power frequency spectrum, with which the frequency composition of a signal is determined. The spectrum power was monitored with the given frequency. The variation of stress calibration curves indicated a linear dependence between the spectrum power with the given frequency and the mechanical stress in the material.

The measurements performed on the shot-peened specimens confirm that the micro-magnetic method is very efficient in assessing the state of material under different shot-peening conditions, including the prediction of the average residual stress, i.e. the variation of residual stress in the shot-peened layer.

REFERENCES

1. D.C. Jiles, R. Kern, W.A. Theiner: Evaluation of Surface Modifications in High Strength Steel, The Sixth Int. Conf. on Shot Peening, San Francisco 1996, USA, Ed.: J. Champaigne, p.p. 192-206.

2. H. Chang, F.C. Schoenig, J.A. Soules: Non-destructive Residual Stress Measurement with Using Eddy Current, The Sixth Int. Conf. on Shot Peening, San Francisco 1996, USA, Ed.: J. Champaigne, p.p. 356-384.

3. D. Barac, W. Katcher, J. Soules: Advances in Eddy Current Measurement of Residual Stress, 7th Int. Conf. on Shot Peening, Warsaw 1999, Poland, Ed.: A. Nakanieczny, p.p. 326-335.

4. G. Dybiec, M. Dybiec: Control Effects by Shot Peening with Application of the Eddy Current Method, 7th Int. Conf. on Shot Peening, Warsaw 1999, Poland, Ed.: A. Nakanieczny, p.p. 321-325.

5. R. Herzog, W. Zinn, B. Scholtes, H. Wohlfahrt: The Significance of Almen Intensity for the Generation of Shot Peening Residual Stresses, The Sixth Int. Conf. on Shot Peening, San Francisco 1996, USA, Ed.: J. Champaigne, p.p. 270-281.

6. B. Scholtes: Eigenspanungen in mechanish raund schicht – verformten werkstoffzuständen Ursachen, Ermittlung und Bewertung, DGM Informationsgesellschaft mbH Verlag, Oberursel 1991, p.p.236.

7. J. Grum, P. Žerovnik: Use of the Barkhausen effect in the measurement of residual stresses in steel, Insight Vol.42, No.12, 2000, p.p. 796-800.

8. L. Suominen, K. Tiitto: Use of X-ray Diffraction and Barkhausen Noise for the Evaluation of Stresses in Shot Peening, Proc. of 4th Int. Conf. on Residual Stresses, Baltimore 1994, USA, p.p. 443-448.

9. O. Vöhringer: Changes in the State of Material by Shot Peening, Ed. Wohlfahrt R., R. Kopp, O. Vöhringer: DGM Informationsgesellshaft, Oberusel 1987, p.p.185-204.

Dr. Janez Grum is a professor for the field Materials Science and Technology of Materials at Faculty of Mechanical Engineering, University of Ljubljana, Slovenia. He graduated with a Ph.D. in technical cybernetics, manufacturing systems and computer technology at Faculty of Mechanical Engineering University of Ljubljana in 1977. He is currently Head of Department for Technology of Materials (since 1993), Head of the Laboratory for Heat Treatment and Laboratory for Materials Testing and President of Slovenian Society for Non-destructive Testing.

He is also editor of the Journal News of Society for Nondestructive Testing, Slovenian Society for Non – Destructive Testing, Ljubljana, Slovenia (since 1994); Member of the Editorial Board, Acta Stereologica Journal for Stereology and Quantitative Image Analysis – Int. Society for Stereology (1978-2000); Member of the Editorial Board, CIRP – Journal of Manufacturing Systems (1997-2000).

For Information:

Faculty of Mechanical Engineering

Askerceva 6

1000 Ljubljana, Slovenia, P.O. Box 394

Tel. +386.1.477 1203, Fax 251 8567

E-mail: janez.grum@fs.uni-lj.si