E-Archive

Interview

in Vol. 25 - January Issue - Year 2024

Shot Peening Technology Setting New Standards in Aerospace Engineering

Leo Ge is the founder of Peentech Group and he is the Chief Technology Officer (CTO) of Shanghai Peentech Equipment Tech. Co., Ltd.

Figure 1: Shot peening machine for aviation parts

Figure 2: Shot peening machine for aircraft engine parts

Figure 3: Shot peening machine for engine shaft inner cavity and outer wall

Figure 4: Shot peening process for aircraft engine parts

Figure 5: Aircraft skin shot peening molding machine

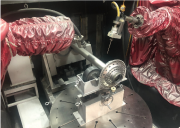

Figure 6: Double-robotic shot blasting machines

MFN was able to get an interview with the Chief Technology Officer (CTO) of Shanghai Peentech Equipment Tech.Co.,Ltd.

(?) MFN: Can you provide an overview of Peentech Group, encompassing details such as its year of establishment, primary areas of operation, and the sectors it caters to?

(!) L. G.: Peentech Group, founded in 2010, has emerged as a prominent supplier of impact strengthening solutions in China. Since its inception, it has carved a remarkable niche for itself as a premier provider of such solutions within China. The company's clientele spans a diverse array of industries, including automobiles, aviation, wind power, petroleum, trains, ships, and beyond. Presently, Peentech boasts an impressive workforce of approximately 250+ dedicated individuals, among whom are few distinguished doctorate degree holders and many accomplished master's degree graduates. Across the nation, the company operates three state-of-the-art manufacturing bases strategically located in Shanghai, Shenyang, and Chongqing. These bases are not only production hubs but also house to cutting edge Research and Development (R&D) facilities, underscoring Peentech Group’s commitment to innovation and excellence. We’ve already achieved numerous successful experiments, solidifying our track record of accomplishment. At the heart of Peentech Group's mission lies a steadfast dedication to impact strengthening solutions. The company's primary business operations revolve around the manufacture of high-quality shot blasting equipment and the provision of comprehensive impact strengthening services.

(?) MFN: Thanks for the company introduction. Can you provide a list of the key aerospace components that your company subjects to shot peening for the purpose of enhancing their performance and durability?

(!) L. G.: Certainly. In the aerospace industry, we have applied shot peening to a variety of critical components, including landing gear struts, landing gear beams, landing gear wheel hubs, landing gear shock absorbers, and retractable landing gear mechanisms. Furthermore, engine components such as turbine blades, turbine discs, engine shafts, compressor blades, combustion chambers, and engine casings, as well as various aircraft structural components like wing spars, have all been subjected to shot peening to enhance their durability and lifespan.

(?) MFN: What features and capabilities does Peentech Group’s CNC shot peening machine offer for aviation component manufacturing, and how does it address the challenges in the aerospace industry?

(!) L. G.: Peentech Group's CNC shot peening machine is specifically tailored for aviation components, offering a range of advanced features and capabilities to meet the precise demands of the aerospace industry. These include high structural compatibility for various aviation components, such as long axis workpieces, inner holes, grooves, deep hole inner walls, and complex surfaces. The machine is equipped with dual robots, specialized nozzles, sorting and recycling systems and a user-friendly interface for real-time monitoring and data recording to ensure repeatability and traceability in part processing. Peentech Group's machine addresses the challenges posed by diverse materials, complex designs, and high manufacturing accuracy in the aviation industry, making it a valuable asset for aviation component manufacturers.

(?) MFN: Can you describe the significance of Peentech Group's involvement in the shot peening projects for aviation parts, and how did it contribute to the aerospace industry?

(!) L. G.: We have a proven track record of successfully completing numerous projects in the aviation industry. I will discuss some of our renowned projects conducted for various companies. Our multifunctional CNC shot peening project initiatives have played a pivotal role in advancing the aerospace sector. As depicted in (Figure 1), our work has addressed intricate requirements of aviation parts, ensuring production of high-quality and reliable components. Similarly, (Figure 2) showcases the shot peening machine's adaptability and efficiency, underlining its critical role in enhancing aviation component manufacturing. Another notable project, as illustrated in (Figure 3), focused on shot peening for aircraft parts. This equipment's versatility, demonstrated by its ability to handle challenging tasks such as engine shaft inner cavity and outer wall shot peening, highlights its practicality and efficiency. Peentech Group has consistently met the precision and product range demands of various companies. In 2021, we provided a comprehensive solution for aircraft fuselage skins, as depicted in (Figure 4), showcasing our unwavering commitment to precision.

In the same year, we introduced the machine illustrated in (Figure 5), capable of shot peening aircraft fuselage skins, integral beams, landing gears, disc shafts, and more. Each motion system of the machine is equipped with an accuracy detector to ensure repeatable positioning accuracy within ±1mm. The process repeatability is further verified to be ≤±0.025mm, demonstrating our dedication to achieving consistent and precise results. (Figure 6) showcases our recent renowned project in 2023, double-robotic shot blasting machine, which emphasizes our dedication to providing advanced solutions for aviation component manufacturing.

This included a set of double-robotic shot blasting machines, incorporating both a robot sandblasting machine and a wet sandblasting machine. These machines have met the same precision and product range requirements as imported equipment and have received recognition from various companies.

(?) MFN: How does the sorting system tackle material diversity and improve abrasive replacement efficiency in aviation machinery?

(!) L. G.: The sorting system we've developed is compatible with both metallic and non-metallic abrasives, and it contains a magnetic sorting device with a precision on-off valve to completely separate these abrasives. Additionally, a fully filtered double-layer vibrator ensures that the abrasives always meet AMS 2430 standards. This innovation eliminates machine stagnation caused by traditional abrasives, effectively reducing costs and improving efficiency.

(?) MFN: Considering your expertise in serving the aerospace industry, could you elaborate on the specific key technologies that your company prioritizes in the development of shot peening machines for this sector?

(!) L. G.: Certainly. Our commitment to the aerospace industry drives us to continually refine our shot-peening technology. We place a strong emphasis on research and development that is closely aligned with the unique characteristics and stringent demands of the aerospace shot-peening process. Our core focus is not only to stabilize the shot-peening process but also to enhance precision, efficiency, and reliability. These technologies encompass advanced control systems, precision motion mechanisms, automated monitoring and feedback systems, and innovative nozzle designs, among others. Our aim is to ensure that our shot-peening machines consistently meet the highest industry standards, playing a pivotal role in enhancing the structural integrity and performance of critical aerospace components. This relentless pursuit of excellence in shot-peening technology is where the key point of our success in the aerospace industry lies.

(?) MFN: Thanks, Leo Ge, for taking the time for this interview. Do you have any final thoughts or messages you'd like to share with our readers?

(!) L. G.: Absolutely, we appreciate the opportunity to discuss our shot peening services tailored for the aircraft industry. At Peentech Group, our mission is to ensure the safety, reliability, and performance of aircraft components through advanced shot peening techniques.

In the aerospace sector, precision and quality are of utmost importance, and shot peening plays a crucial role in achieving these standards. As technology advances, we remain committed to staying at the forefront of shot peening technology, collaborating with industry experts, and investing in cutting-edge equipment.

We encourage our readers to recognize the significance of shot peening in enhancing the structural integrity of aircraft components.

MFN would like to thank Leo Ge for this interview!

For Information:

Shanghai Peentech Equipment Tech.Co.,Ltd.

No. 5861, Huyi Road, Waigang Town,

Jiading District, Shanghai 201806,

China

Tel. +86.021.59529798

E-mail: leo.ge@peentech.cn