E-Archive

Articles

in Vol. 3 - May Issue - Year 2002

Electronics Inc. & MFN's Official Shot Peening Training made available to the Industry!

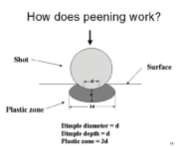

slide from chapter "introduction"

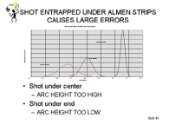

slide from chapter "peening intensity"

slide from chapter "peening intensity"

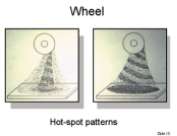

slide from chapter "peening location"

slide from chapter "peening machines & equip."

slide from chapter "peening machines & equip."

slide from chapter "peening machines & equip."

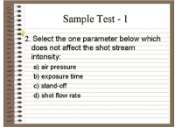

slide from chapter "sample test"

Electronics Incorporated, the publisher of the magazine "The Shot Peener" and MFN decided to combine their resources to design a shot peening training to determine a standard of qualification for operators and supervisors working in this field.

In the last few years the shot peening process has established itself to be, depending on application, implemented in the design of high performance parts. Furthermore, in the aviation industry peening is regarded as a critical process. Despite of all this, there is up to now not a single school for professionals, a college or university, which offers peening as part of their study program. Except the "Shot Peener Certificates" level 1 to level 3 provided by EI & MFN during workshops, there are no means for a person in this field to prove a qualification. This is not just unrewarding for the person having the qualification, it also puts the employer in a very difficult situation.

But even more important, it can create a process quality problem which finally could lead into a safety hazard. After all, the largest amount of peening is done on either cars or aeroplanes.

In-house Training

The shot peening shops which face the consequences of this situation on a frequent basis, are presently in a position to solve the problem all by themselves. So those peening job shops which have to pass audits were forced to create their own shot peening training. In the aviation industries there are manufacturers which, besides others, also want to see the complete training volume as part of their approval process. This is naturally a big burden for a peening shop, since its prime responsibility is to ensure a high quality of the process and not to design training programs. And even if a peening shop has a fine training, it is still far away from creating a standard in the industry. Furthermore, since the content of the training is not supervised, there is always the chance that certain procedures are misunderstood and than taught in the wrong fashion.

Qualified Shot Peening Training

Electronics Inc. and MFN have acknowledged this problem for a long time. A first step in the direction of creating a standard for training in the peening industry was to host workshops, which have been carried out for over a decade in the USA and recently as well in Singapore. And by issuing different levels of "Shot Peener Certificates" certain means of measuring the qualification of a person have been made possible.

Presently EI and MFN are approaching various manufacturer in the aviation industries to ask for their acceptance statement or approval of the training.

Peening Training to be franchised to the Industries

The demand for a qualified peening training is so large, that it can not be served with a few workshop events a year. Even additional on-site training can not satisfy the global demand. EI & MFN therefore decided to design a training concept which gives the peening shops the opportunity to either self study the contents or to assign a supervisor to present it to the operators. The training comes as hard copy and on CD with complete POWER POINT presentations. The training is offered to anybody in the industry. Depending on the customer there will be different licence agreements. The training is subject to constant changes and every year a new version will be released. Using this philosophy EI & MFN believes to have created an excellent tool to provide global access to a particular standard in terms of peening training.

The Contents of the Official Electronics Inc. & MFN Shot Peening Training

The training contents is the result of the experience as well as material collected in over a decade of hosting workshops. It will not just cover the basic knowledge of peening, it has also the information needed for an operator to pass the very strict audits carried out by manufacturers of the aviation industries. If a peening shop has to carry out work for such manufacturers, the shop will be audited on a yearly basis. Depending on the audit, such inspectors might question every single detail of the process. Things like the frequent calibration of key elements, the paper work, how does one verify the hardness of shot or Almen strips, etc.. Those audits are so stiff, that EI & MFN decided to dedicate two chapters just to cover this subject.

The training also provides all the know-how needed to obtain a "Level 3 Shot Peener" certificate, which normally signifies that a person is qualified to teach others about peening. In general the following chapters are covered:

-Introduction to Peening

-Peening Intensity

-Peening Coverage

-Peening Location

-Peening Media

-Peening Machines & Equipment

-Specificat. & Standard Practices

-Audit for Shot Peening

-A Case Study (survive an audit)

-Sample Test

Almen Saturation Curve Program

In addition to the Power Point presentations, a completely independent Almen saturation curve program is provided. It will read out T and 2T, indicate faulty Arc height values as well as combine the information of up to 4 different Almen test series. Furthermore one can individually create an own protocol and save all the Almen curves on hard disk or print them out. It runs on any Windows based computer.For more information concerning the training or the franchise possibilities contact either EI or MFN.

For information:

Jack Champaigne

Electronics Inc. (USA)

Tel: +1.574.256 5001

E-mail: info@shotpeener.com

www.shotpeener.com

For information:

Metal Finishing News

Tel: +41.1.810 7377

E-mail:

info@metal-finishing-news.com